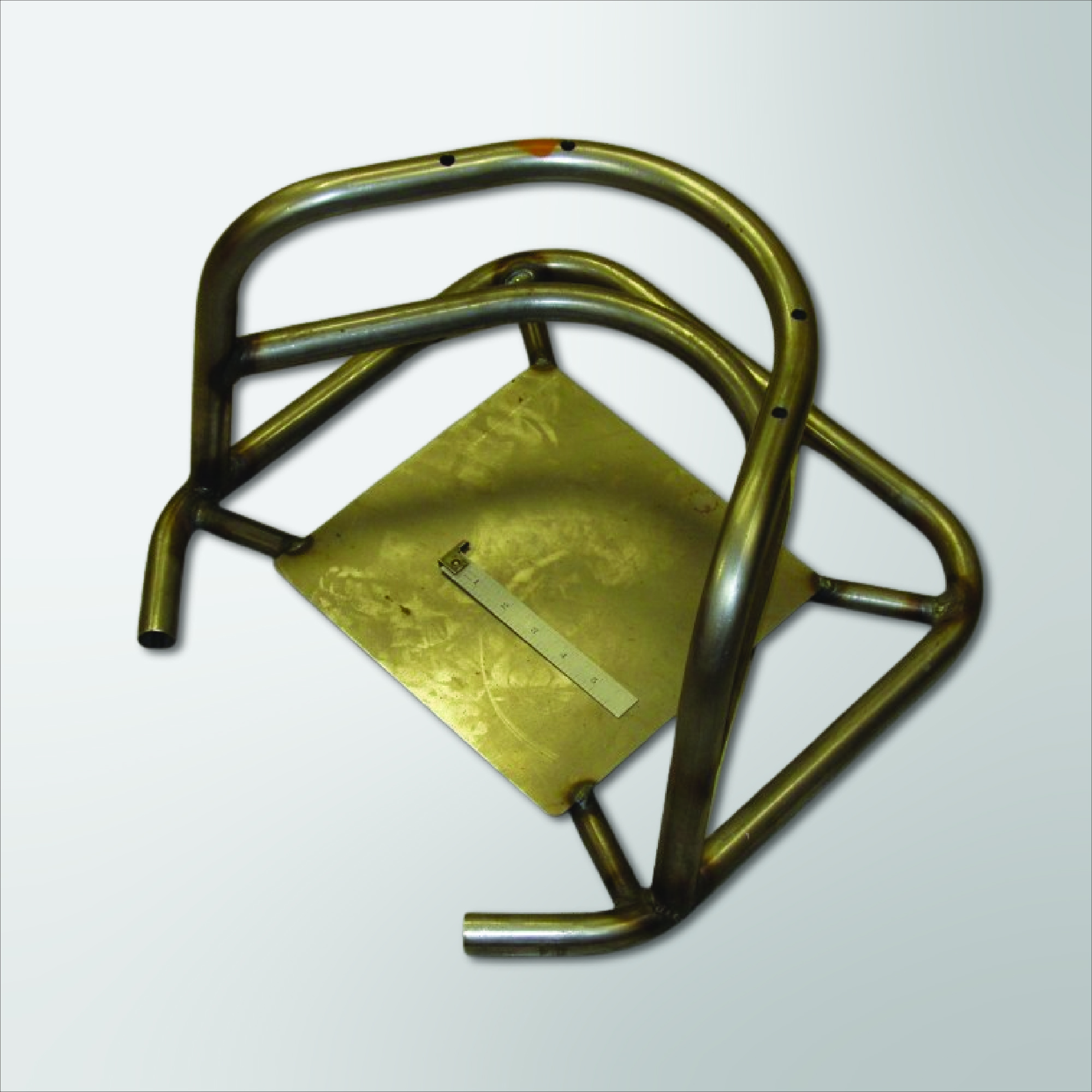

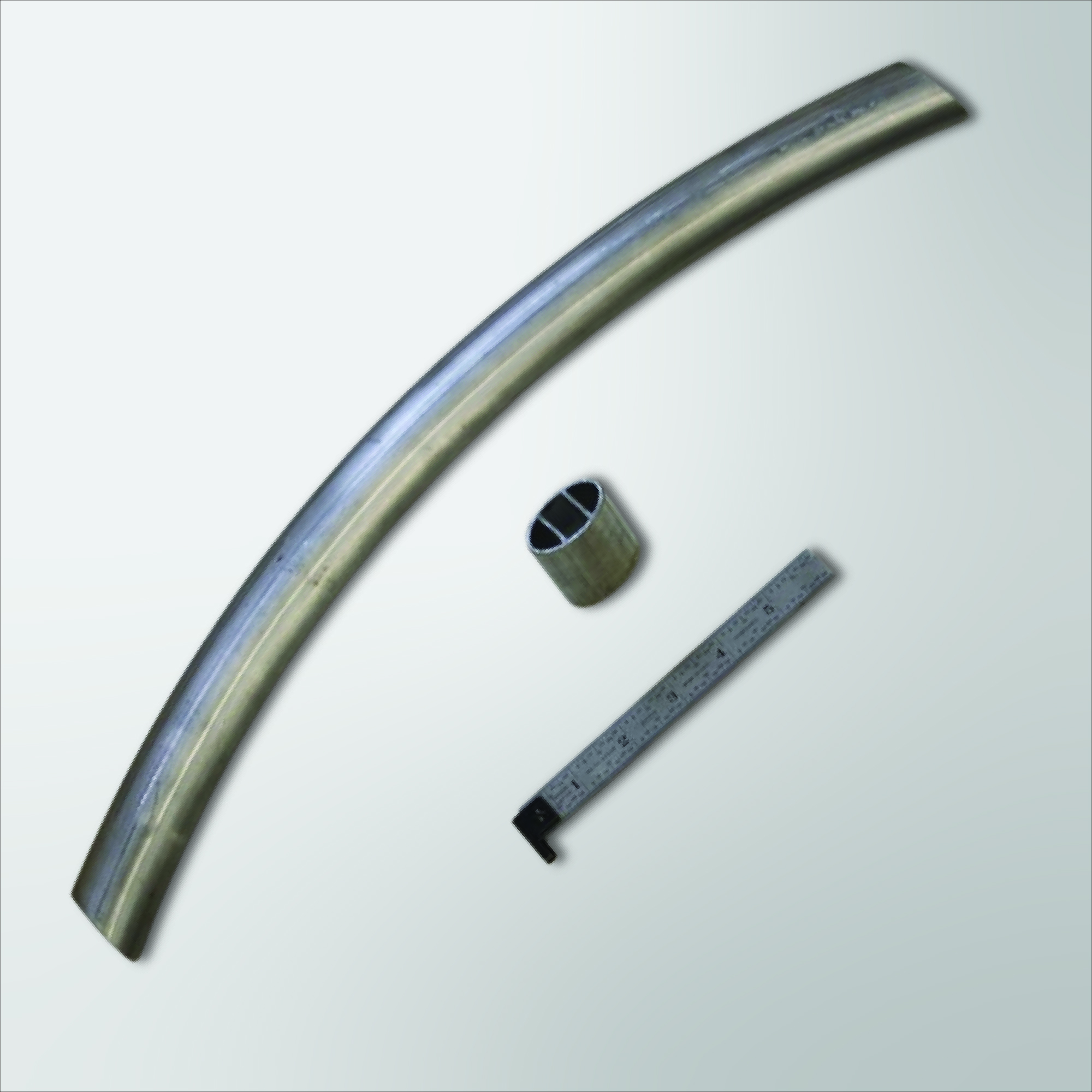

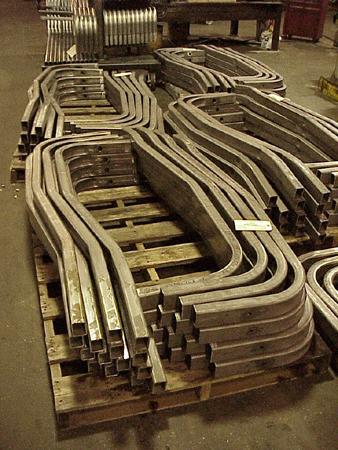

Tube Bending & Fabricating

With over 75 years of experience in tube bending and fabrication, Bassett Industries, Inc. is a true vertically integrated turnkey tubular and sheet metal parts and assembly manufacturer. We take on a wide variety of precision tube fabrication processes from pre-cutting of raw materials to final production of finished, fabricated tubular components and assemblies.