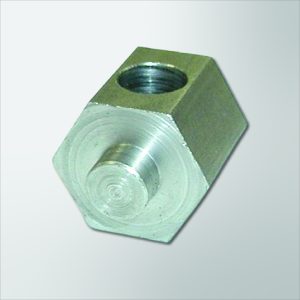

CNC Machining

Bassett Industries, Inc. provides precision CNC machining services including turning, milling, and drilling, with travel up to 10ft. Our CNC machining services are practical options for production volumes ranging from prototype manufacturing to high-volume production runs.