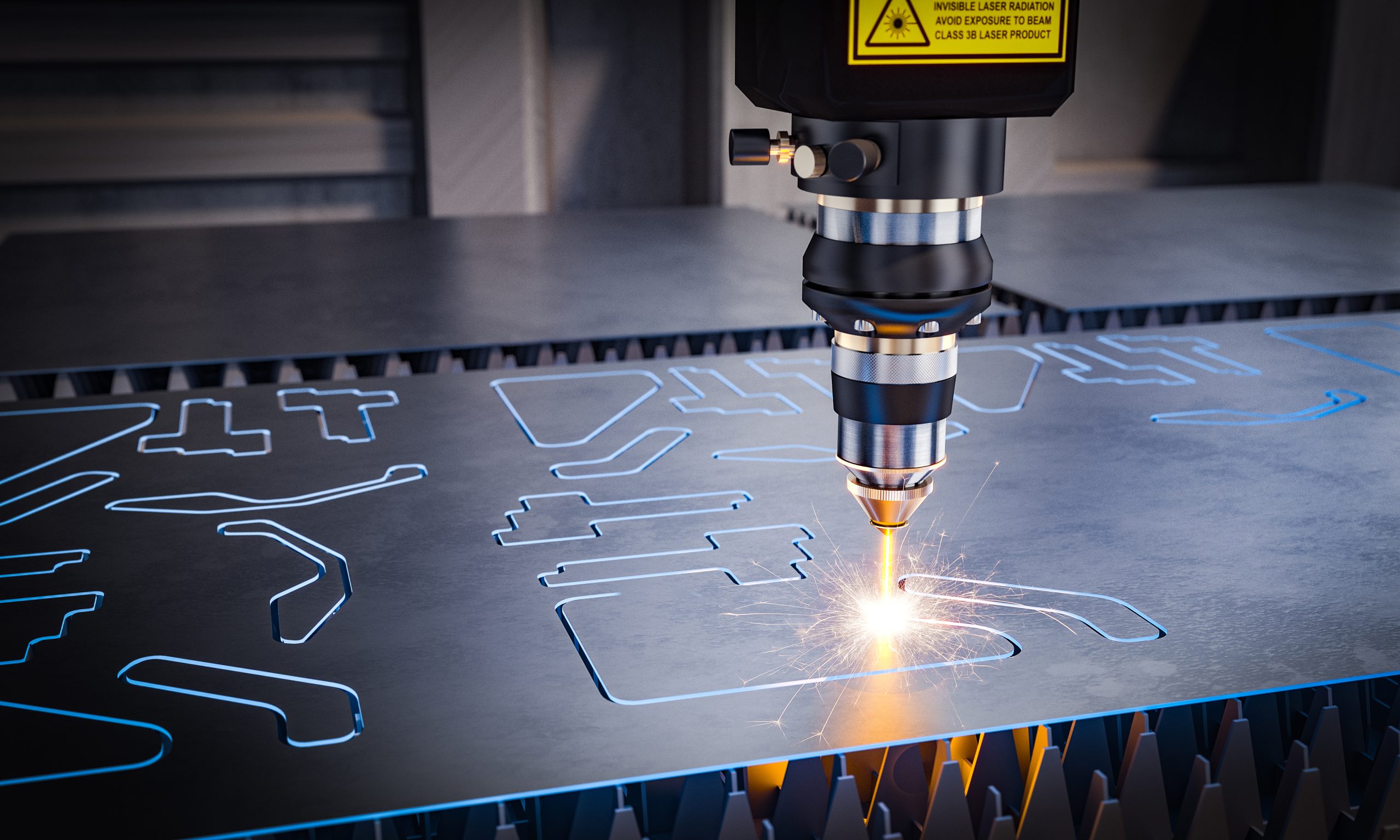

Laser Cutting

Bassett Industries, Inc. offers comprehensive laser cutting services for short and long production runs. Our multiple laser cutting systems including, fiber up to 8KW 4 meter x 2 meter, 6 ft x 12ft CO2, flat sheet, 5 axis and tube cutting machines will meet the demands for any customer application.