Sheet Metal Forming

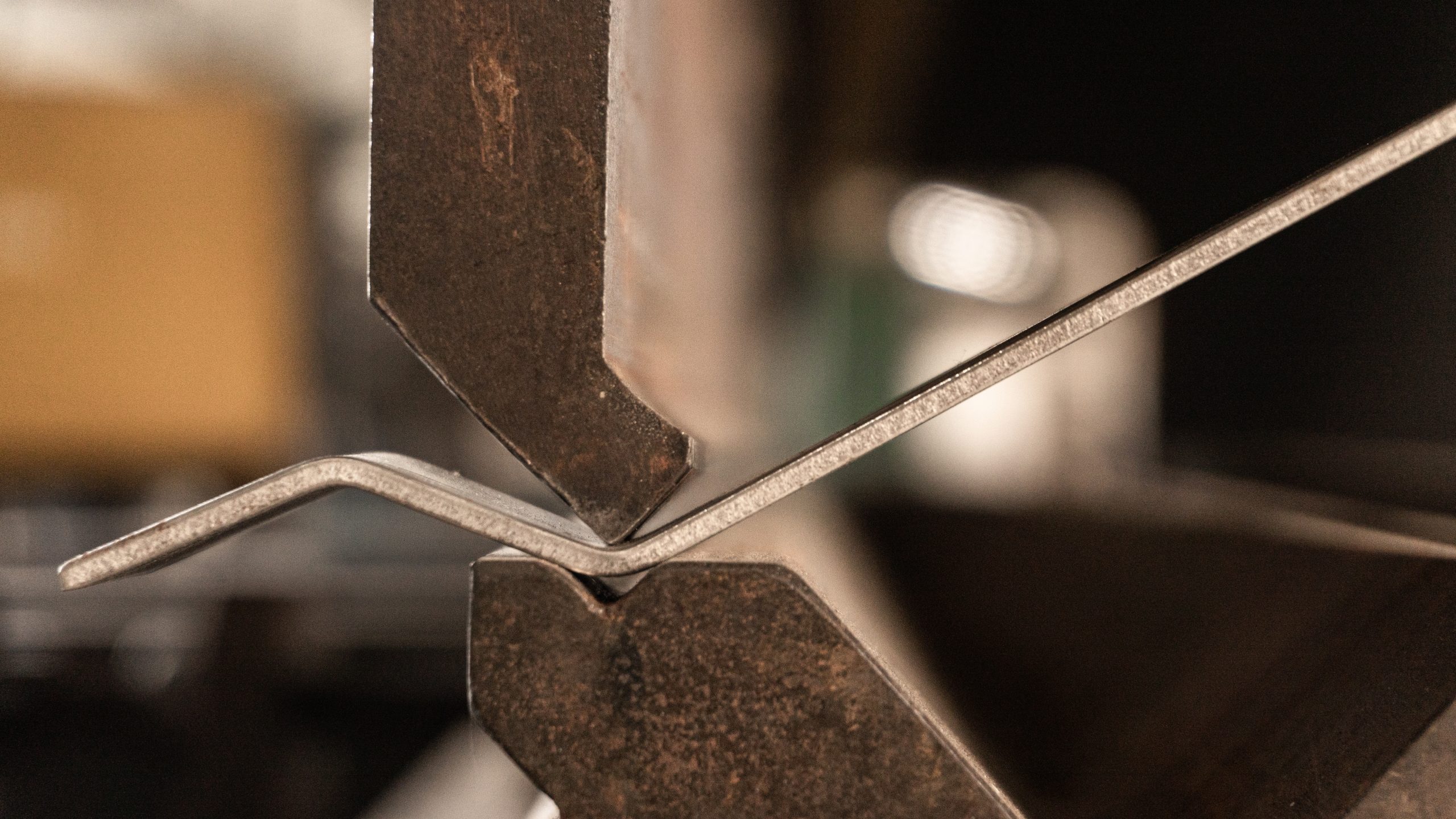

Bassett Industries, Inc. uses CNC press brake machines driven by CAD/CAM programming for precision bending and forming of sheet metal parts that meet or beat customer requirements and specifications.

Bassett Industries, Inc. uses CNC press brake machines driven by CAD/CAM programming for precision bending and forming of sheet metal parts that meet or beat customer requirements and specifications.

Our CNC press brakes are capable of bending and shaping sheet metal with capacities up to 350 tons, and our systems are equipped with a 9 axis back gauge to ensure repeatable positions.

Touch screen programmable CNC controls in our metal forming systems with unlimited offline capabilty program. With the help of our comprehensive set of in-house dies, including radius dies and hemming dies, we offer quick turnaround and short lead times for our CNC bent and formed parts.

Contact Us TodayOur sheet metal forming capabilities include a maximum bending length of 4,100 mm (161.42″) and forming power up to 320 metric tons (353 short tons). We offer a full range of fabrication services including MIG, TIG, and spot welding, laser cutting, roll bending, saw cutting, swaging, and flaring ensuring precision and versatility for projects of all sizes.

Some basic ideas that can help in reducing the overall cost of a part by designing the part to be manufacturing friendly are provided below. For a more in depth analysis send us your drawings, or call one of our engineers.

Send us your specs or drawings, and our team will review the details and provide a custom quote. We’re here to deliver precision, efficiency, and reliable turnaround from start to finish.